Constructing a robotic that would choose up delicate objects like eggs or blueberries with out crushing them took plenty of management algorithms that course of feeds from superior imaginative and prescient techniques or sensors that emulate the human sense of contact. The opposite means was to take a plunge into the realm of soppy robotics, which normally means a robotic with restricted energy and sturdiness.

Now, a crew of researchers at Harvard College printed a examine the place they used a easy hydraulic gripper with no sensors and no management techniques in any respect. All they wanted was silicon oil and plenty of tiny rubber balls. Within the course of, they’ve developed a metafluid with a programmable response to strain.

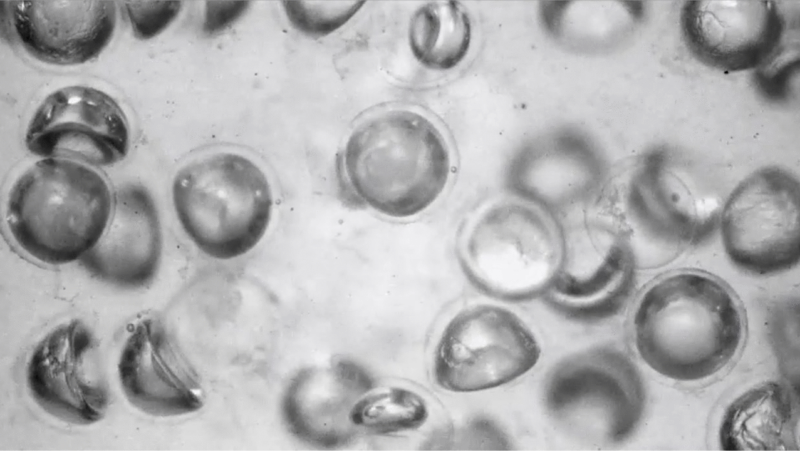

Swimming rubber spheres

“I did my PhD in France on making a spherical shell swim. To make it swim, we had been making it collapse. It moved like a [inverted] jellyfish,” says Adel Djellouli, a researcher at Bertoldi Group, Harvard College, and the lead writer of the examine. “I advised my boss, ‘hey, what if I put this sphere in a syringe and improve the strain?’ He stated it was not an fascinating thought and that this wouldn’t do something,” Djellouli claims. However a couple of years and a few rejections later, Djellouli met Benjamin Gorissen, a professor of mechanical engineering on the College of Leuven, Belgium, who shared his pursuits. “I may do the experiments, he may do the simulations, so we thought we may suggest one thing collectively,” Djellouli says. Thus, Djellouli’s rubber sphere lastly bought into the syringe. And outcomes had been fairly surprising.

The sphere has a radius of 10 mm, and its 2-mm-thick silicone rubber partitions encompass a pocket of air. It was positioned in a container with 300 ml of water. When the strain within the container began to extend, the sphere, at 120 kPa, began to buckle. As soon as it began to buckle, strain remained comparatively regular for some time, despite the fact that the quantity occupied by the fluid continued dropping. The liquid with a sphere in it didn’t behave like water anymore—it had a pronounced plateau in its strain/quantity curve. “Metafluids—liquids with tunable properties that don’t exist in nature—had been theorized by Federico Capasso and colleagues, who needed to attain a liquid with unfavorable refractive index. They began with optics again then, however wanting on the habits of water with this rubber sphere in it, we knew what we had was a metafluid,” says Djellouli.

Mixing programmable fluids

Placing a single rubber sphere within the water was simply a place to begin. “I at all times had this concept at the back of my head: Like, what would occur if I put in plenty of them?” Djellouli advised Ars. So, his crew began to experiment with completely different sizes and numbers of the spheres within the medium and utilizing completely different mediums like silicon oil. “You possibly can tune strain at which the spheres activate by altering their radius and thickness of their partitions. While you make the spheres thicker, you want extra vitality to make them buckle and thus the activation strain shall be greater,” explains Djellouli.

There are different parameters that may be modified to program desired properties within the metafluid. These embody the quantity fraction—mainly how a lot of the entire fluid’s quantity is taken by the spheres—and the construction of the spheres, because the fluid behaves in a different way once you put spheres with completely different sizes and thickness in it. You can too tune this through the use of mixtures of spheres with completely different properties. “If the variation in dimension and thickness of the spheres could be very tight, you’re going to have a really flat plateau of strain once they activate. In case you have a wider distribution, the transition from all unbuckled to all buckled shall be smoother,” says Djellouli. Utilizing completely different mixtures of spheres additionally permits a number of plateaus at completely different pressures in a single fluid. “This manner you possibly can exactly tune the strain/quantity curve,” Djellouli provides.

By tuning these curves, his crew managed to construct a sensible hydraulic gripper that works with out the necessity for sensors or management techniques.